A team of scientists at the UK’s number one ranked university have developed a way of making liquid fuels using the power of the sun to pull carbon dioxide from the air and make synthesis gas.

This is basically a mixture of hydrogen and carbon monoxide (CO) in various ratios, and the process is the latest development in so-called direct air capture (DAC).

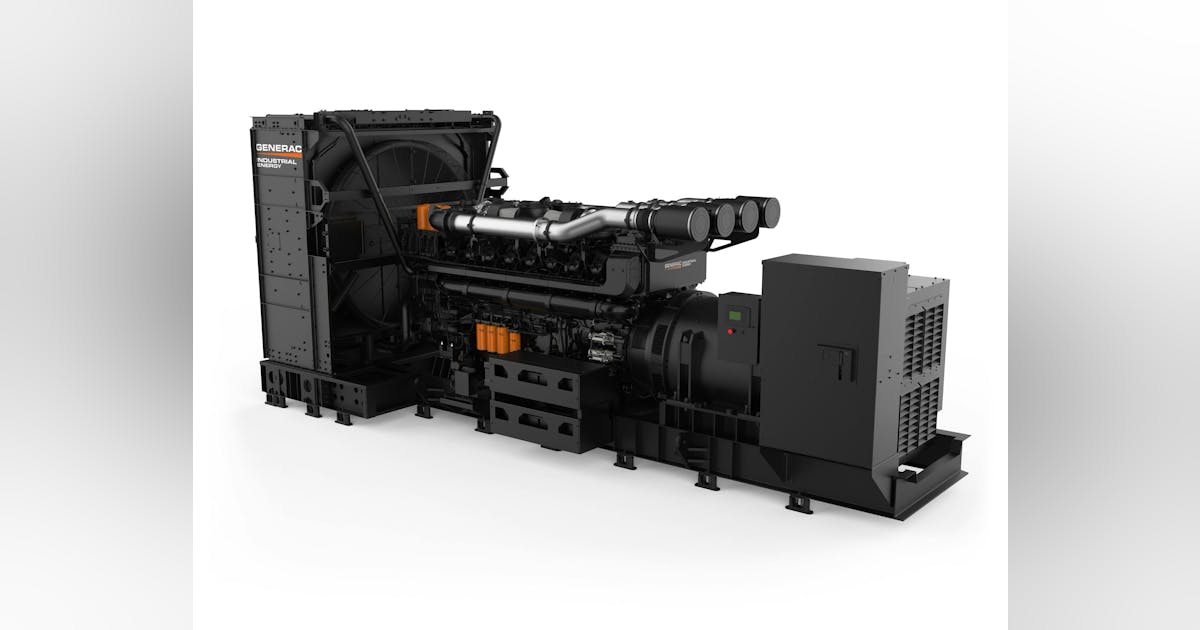

The reactor has been developed by Cambridge University researchers who claim the output of their solar panel-powered reactor could be used as a feedstock to make fuels and the many chemicals and pharmaceutical products we rely on.

The researchers say their system is compact and simple enough to be deployed in off-grid locations.

Unlike most carbon capture technologies, the DAC reactor developed by the Cambridge team does not require fossil-fuel-based power, or the transport and storage of CO2.

It literally can convert atmospheric CO2 into hydrocarbon gas using sunlight and is inspired by one of nature’s greatest processes – photosynthesis.

In the UK, carbon capture and storage (CCS) has long been touted as a way of securely dumping below ground the CO2 produced in industrial processes as a partial mitigation of Earth’s accelerating climate crisis.

But CCS per se is energy-intensive and there are concerns about the long-term safety of storing pressurised CO2 deep underground long-term.

Though there is the CCUS (utilisation) option to consider too.

According to the International Energy Agency, around 45 commercial facilities are already in operation applying CCUS to industrial processes, fuel transformation and power generation.

CCUS deployment has trailed behind expectations in the past, but momentum has grown substantially in recent years, with over 700 projects in various stages of development across the CCUS value chain.

© Supplied by Reisner Lab, Cambrid

© Supplied by Reisner Lab, Cambrid“Aside from the expense and the energy intensity, CCS provides an excuse to carry on burning fossil fuels, which is what caused the climate crisis in the first place,” says Professor Erwin Reisner, leader of the Cambridge team at the university’s Reisner Lab.

“Instead of continuing to dig up and burn fossil fuels to produce the products we have come to rely on, we can get all the CO2 we need directly from the air and reuse it.

“We can build a circular, sustainable economy – if we have the political will to do it.”

The focus of Reisner’s research group is the development of devices that convert waste, water and air into practical fuels and chemicals.

Their approach is also claimed to be easier to scale up than earlier solar-powered devices.

The device, a solar-powered flow reactor, uses specialised filters to grab CO2 from the air at night, like how a sponge soaks up water.

When the sun comes out, the sunlight heats up the captured CO2, absorbing infrared radiation, and a semiconductor powder absorbs the ultraviolet radiation to start a chemical reaction that converts the captured CO2 into solar syngas.

A mirror on the reactor concentrates the sunlight, making the DAC process more efficient.

The researchers are currently working on converting the solar syngas into liquid fuels that can be combusted without adding more CO2 to the atmosphere.

Reisner believes that if his approach can be scaled up, they could solve two problems at once: removing CO2 from the atmosphere and creating a clean, versatile alternative to fossil fuels.

A particularly promising opportunity is in the chemical and pharmaceutical sector, where syngas can be converted into many of the products we rely on every day, without contributing to climate change.

The Cambridge team are building a larger-scale version of the reactor and hopes to complete and start production trials shortly.

If successfully scaled up, they say their reactor could be used in a decentralised way, so that individuals could theoretically generate their own fuel, which would be useful in remote or off-grid locations.

The technology is being commercialised with the support of Cambridge Enterprise, the University’s commercialisation arm.

The research was supported in part by UK Research and Innovation (UKRI), the European Research Council, the Royal Academy of Engineering, and the Cambridge Trust.

Erwin Reisner is a Fellow of St John’s College, Cambridge.