Fusion energy holds the potential to shift a geopolitical landscape that is currently configured around fossil fuels. Harnessing fusion will deliver the energy resilience, security, and abundance needed for all modern industrial and service sectors. But these benefits will be controlled by the nation that leads in both developing the complex supply chains required and building fusion power plants at scales large enough to drive down economic costs.

The US and other Western countries will have to build strong supply chains across a range of technologies in addition to creating the fundamental technology behind practical fusion power plants. Investing in supply chains and scaling up complex production processes has increasingly been a strength of China’s and a weakness of the West, resulting in the migration of many critical industries from the West to China. With fusion, we run the risk that history will repeat itself. But it does not have to go that way.

The US and Europe were the dominant public funders of fusion energy research and are home to many of the world’s pioneering private fusion efforts. The West has consequently developed many of the basic technologies that will make fusion power work. But in the past five years China’s support of fusion energy has surged, threatening to allow the country to dominate the industry.

The industrial base available to support China’s nascent fusion energy industry could enable it to climb the learning curve much faster and more effectively than the West. Commercialization requires know-how, capabilities, and complementary assets, including supply chains and workforces in adjacent industries. And especially in comparison with China, the US and Europe have significantly under-supported the industrial assets needed for a fusion industry, such as thin-film processing and power electronics.

To compete, the US, allies, and partners must invest more heavily not only in fusion itself—which is already happening—but also in those adjacent technologies that are critical to the fusion industrial base.

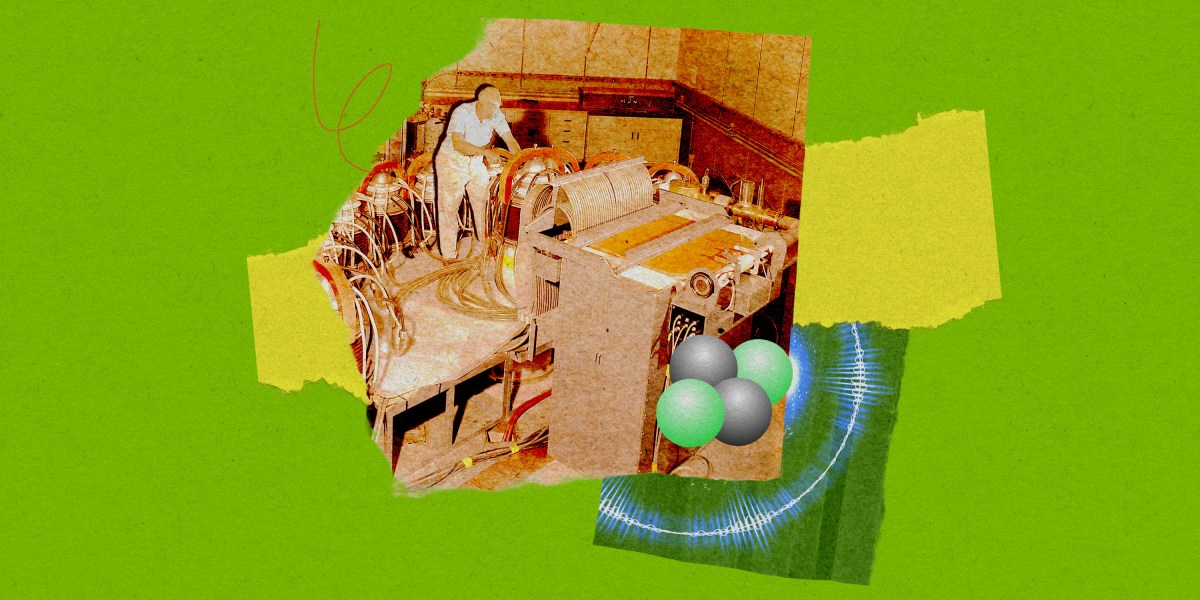

China’s trajectory to dominating fusion and the West’s potential route to competing can be understood by looking at today’s most promising scientific and engineering pathway to achieve grid-relevant fusion energy. That pathway relies on the tokamak, a technology that uses a magnetic field to confine ionized gas—called plasma—and ultimately fuse nuclei. This process releases energy that is converted from heat to electricity. Tokamaks consist of several critical systems, including plasma confinement and heating, fuel production and processing, blankets and heat flux management, and power conversion.

A close look at the adjacent industries needed to build these critical systems clearly shows China’s advantage while also providing a glimpse into the challenges of building a fusion industrial base in the US or Europe. China has leadership in three of these six key industries, and the West is at risk of losing leadership in two more. China’s industrial might in thin-film processing, large metal-alloy structures, and power electronics provides a strong foundation to establish the upstream supply chain for fusion.

The importance of thin-film processing is evident in the plasma confinement system. Tokamaks use strong electromagnets to keep the fusion plasma in place, and the magnetic coils must be made from superconducting materials. Rare-earth barium copper oxide (REBCO) superconductors are the highest-performing materials available in sufficient quantity to be viable for use in fusion.

The REBCO industry, which relies on thin-film processing technologies, currently has low production volumes spanning globally distributed manufacturers. However, as the fusion industry grows, the manufacturing base for REBCO will likely consolidate among the industry players who are able to rapidly take advantage of economies of scale. China is today’s world leader in thin-film, high-volume manufacturing for solar panels and flat-panel displays, with the associated expert workforce, tooling sector, infrastructure, and upstream materials supply chain. Without significant attention and investment on the part of the West, China is well positioned to dominate REBCO thin-film processing for fusion magnets.

The electromagnets in a full-scale tokamak are as tall as a three-story building. Structures made using strong metal alloys are needed to hold these electromagnets around the large vacuum vessel that physically contains the magnetically confined plasma. Similar large-scale, complex metal structures are required for shipbuilding, aerospace, oil and gas infrastructure, and turbines. But fusion plants will require new versions of the alloys that are radiation-tolerant, able to withstand cryogenic temperatures, and corrosion-resistant. China’s manufacturing capacity and its metallurgical research efforts position it well to outcompete other global suppliers in making the necessary specialty metal alloys and machining them into the complex structures needed for fusion.

A tokamak also requires large-scale power electronics. Here again China dominates. Similar systems are found in the high-speed rail (HSR) industry, renewable microgrids, and arc furnaces. As of 2024, China had deployed over 48,000 kilometers of HSR. That is three times the length of Europe’s HSR network and 55 times as long as the Acela network in the US, which is slower than HSR. While other nations have a presence, China’s expertise is more recent and is being applied on a larger scale.

But this is not the end of the story. The West still has an opportunity to lead the other three adjacent industries important to the fusion supply chain: cryo-plants, fuel processing, and blankets.

The electromagnets in an operational tokamak need to be kept at cryogenic temperatures of around 20 Kelvin to remain superconducting. This requires large-scale, multi-megawatt cryogenic cooling plants. Here, the country best set up to lead the industry is less clear. The two major global suppliers of cryo-plants are Europe-based Linde Engineering and Air Liquide Engineering; the US has Air Products and Chemicals and Chart Industries. But they are not alone: China’s domestic champions in the cryogenic sector include Hangyang Group, SASPG, Kaifeng Air Separation, and SOPC. Each of these regions already has an industrial base that could scale up to meet the demands of fusion.

Fuel production for fusion is a nascent part of the industrial base requiring processing technologies for light-isotope gases—hydrogen, deuterium, and tritium. Some processing of light-isotope gases is already done at small scale in medicine, hydrogen weapons production, and scientific research in the US, Europe, and China. But the scale needed for the fusion industry does not exist in today’s industrial base, presenting a major opportunity to develop the needed capabilities.

Similarly, blankets and heat flux management are an opportunity for the West. The blanket is the medium used to absorb energy from the fusion reaction and to breed tritium. Commercial-scale blankets will require entirely novel technology. To date, no adjacent industries have relevant commercial expertise in liquid lithium, lead-lithium eutectic, or fusion-specific molten salts that are required for blanket technology. Some overlapping blanket technologies are in early-stage development by the nuclear fission industry. As the largest producer of beryllium in the world, the US has an opportunity to capture leadership because that element is a key material in leading fusion blanket concepts. But the use of beryllium must be coupled with technology development programs for the other specialty blanket components.

These six industries will prove critical to scaling fusion energy. In some, such as thin-film processing and large metal-alloy structures, China already has a sizable advantage. Crucially, China recognizes the importance of these adjacent industries and is actively harnessing them in its fusion efforts. For example, China launched a fusion consortium that consists of industrial giants spanning the steel, machine tooling, electric grid, power generation, and aerospace sectors. It will be extremely difficult for the West to catch up in these areas, but policymakers and business leaders must pay attention and try to create robust alternative supply chains.

As the industrial area of greatest strength, cryo-plants could continue to be an opportunity for leadership in the West. Bolstering Western cryo-plant production by creating demand for natural-gas liquefaction will be a major boon to the future cryo-plant supply chain that will support fusion energy.

The US and European countries also have an opportunity to lead in the emerging industrial areas of fuel processing and blanket technologies. Doing so will require policymakers to work with companies to ensure that public and private funding is allocated to these critical emerging supply chains. Governments may well need to serve as early customers and provide debt financing for significant capital investment. Governments can also do better to incentivize private capital and equity financing—for example, through favorable capital-gains taxation. In lagging areas of thin-film and alloy production, the US and Europe will likely need partners, such as South Korea and Japan, that have the industrial bases to compete globally with China.

The need to connect and capitalize multiple industries and supply chains will require long-term thinking and clear leadership. A focus on the demand side of these complementary industries is essential. Fusion is a decade away from maturation, so its supplier base must be derisked and made profitable in the near term by focusing on other primary demand markets that contribute to our economic vitality. To name a few, policymakers can support modernization of the grid to bolster domestic demand for power electronics and domestic semiconductor manufacturing to support thin-film processing.

The West must also focus on the demand for energy production itself. As the world’s largest energy consumer, China will leverage demand from its massive domestic market to climb the learning curve and bolster national champions. This is a strategy that China has wielded with tremendous success to dominate global manufacturing, most recently in the electric-vehicle industry. Taken together, supply- and demand-side investment have been a winning strategy for China.

The competition to lead the future of fusion energy is here. Now is the moment for the US and its Western allies to start investing in the foundational innovation ecosystem needed for a vibrant and resilient industrial base to support it.

Daniel F. Brunner is a co-founder of Commonwealth Fusion Systems and a Partner at Future Tech Partners.

Edlyn V. Levine is the co-founder of a stealth-mode technology start up and an affiliate of the MIT Sloan School of Management.

Fiona E. Murray is a professor of entrepreneurship at the MIT School of Management and Vice Chair of the NATO Innovation Fund.

Rory Burke is a graduate of MIT Sloan and a former summer scholar with ARPA-E.