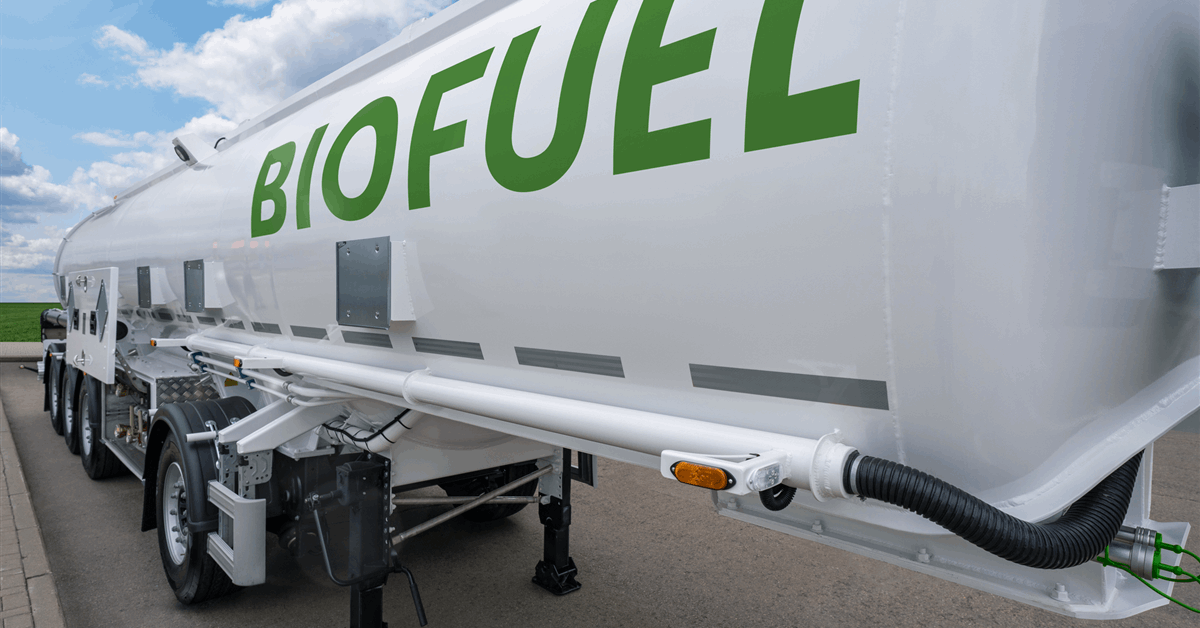

Neste Oyj and Chevron Lummus Global (CLG) have announced promising pilot results for a new process to convert lignocellulosic biomass into renewable fuels.

“Through close collaboration at CLG’s state-of-the-art R&D facility in the U.S., Neste and CLG have successfully demonstrated proof of concept for converting lignocellulosic waste into renewable fuels, with highly promising initial results”, a joint statement said.

The results indicated the new technology could outperform existing technologies for processing lignocellulosic raw materials, according to the companies. “Neste and CLG are currently validating the technology and targeting readiness to scale up the technology to commercial scale”, they said.

“Vast amounts of lignocellulosic waste and residues from existing forest industry and agricultural production remain underutilized and could be leveraged as valuable renewable raw materials”.

“The partnership combines CLG’s extensive experience and proven track record in developing and licensing market-leading refining technologies with Neste’s pioneering expertise and global leadership in renewable fuels”, the partners said.

CLG chief executive Rajesh Samarth said, “We are confident this partnership will pave a new pathway for producing renewable fuels, leveraging our versatile and scalable hydroprocessing technology platform”.

Lars Peter Lindfors, senior vice president for technology and innovation at Neste, said, “Unlocking the potential of these promising raw materials would allow us to meet the growing demand of renewable fuels in the long-term and contribute to ambitious greenhouse gas emission reduction targets”.

Espoo, Finland-based Neste produces sustainable aviation fuel (SAF) and renewable diesel. It has increased its SAF production capacity to 1.5 million metric tons per annum (MMtpa) with last year’s start-up of a Rotterdam project with a capacity of 500,000 metric tons a year. Neste aims to grow its production capacity for renewable fuels to 6.8 million metric tons a year by 2027.

CLG, a joint venture between Chevron Corp. and Lummus Technology, provides technology for the production of both renewable and conventional transportation fuels, premium base oils and more sustainable petrochemicals.

In 2021 CLG launched its ISOTERRA technology for the conversion of biomass into SAF and renewable diesel. The two-step process involves hydrodeoxygenation of feeds such as vegetable, algae and palm and used cooking oils, followed by dewaxing to meet cold flow property specifications.

ISOTERRA was installed in Chevron’s El Segundo Refinery in California in late 2023. Last year ISOTERRA was selected for a SAF project in China.

To contact the author, email [email protected]

What do you think? We’d love to hear from you, join the conversation on the

Rigzone Energy Network.

The Rigzone Energy Network is a new social experience created for you and all energy professionals to Speak Up about our industry, share knowledge, connect with peers and industry insiders and engage in a professional community that will empower your career in energy.

MORE FROM THIS AUTHOR