For decades, power systems engineers have relied on modeling and simulation to ensure efficient and reliable power generation and distribution. Electromagnetic field analysis helps them design grid infrastructure components, structural and acoustics simulation is used to mitigate issues like transformer vibration and noise and electric breakdown and corona discharge analyses are used to accurately predict the performance and safety of high-voltage transmission line systems.

Now, thanks to built-in simulation software capabilities that enable engineers to build custom model-based apps for users without modeling expertise, the scope of who can access advanced simulation technology in power systems organizations has dramatically increased. By building and distributing their own simulation apps, power grid companies are able to extend the benefits of simulation-based decision making to more collaborators within the R&D workflow and even to colleagues in the field. What follows is effective collaboration and accelerated innovation.

Simulation Supports Efficient Transformer Design

Take a company that develops power transformer equipment, for instance. Transformers are inherently noisy, but they can be designed to be as close to silent as possible. As with most things in this world, transformers involve many interconnected physics — electromagnetics, acoustics and structural mechanics, in this case — which means that multiphysics simulation software is the tool for the job when optimizing their designs.

The R&D engineers responsible for coming up with one manufacturer’s new transformer designs all knew how to use finite element analysis (FEA) software, but they worked closely with other teams and departments without such expertise. For example, the designers tasked with building the final transformers had no familiarity with FEA. Instead, they preferred to use spreadsheets and other tools based on statistics and empirical models, which worked well for transformers they built frequently, but not for new designs or scenarios where different dimensions were introduced. In these more complex cases, multiphysics simulation was absolutely necessary to get accurate predictions of how noisy the final transformer would be. Additionally, if the final design were too noisy, the company would have to make costly modifications after the fact. They needed a better approach.

What did they do? They built their own custom simulation apps based on the finite element models. That way, their design team could enter parameters into input fields in a straightforward user interface — built by the engineers in house, customized to suit the company’s needs. Since the apps are powered by their own underlying multiphysics models, the designers could then quickly and accurately analyze how their transformers would hum as a result of different combinations of geometry, material and other design parameters.

Optional Caption

Permission granted by COMSOL, Inc.

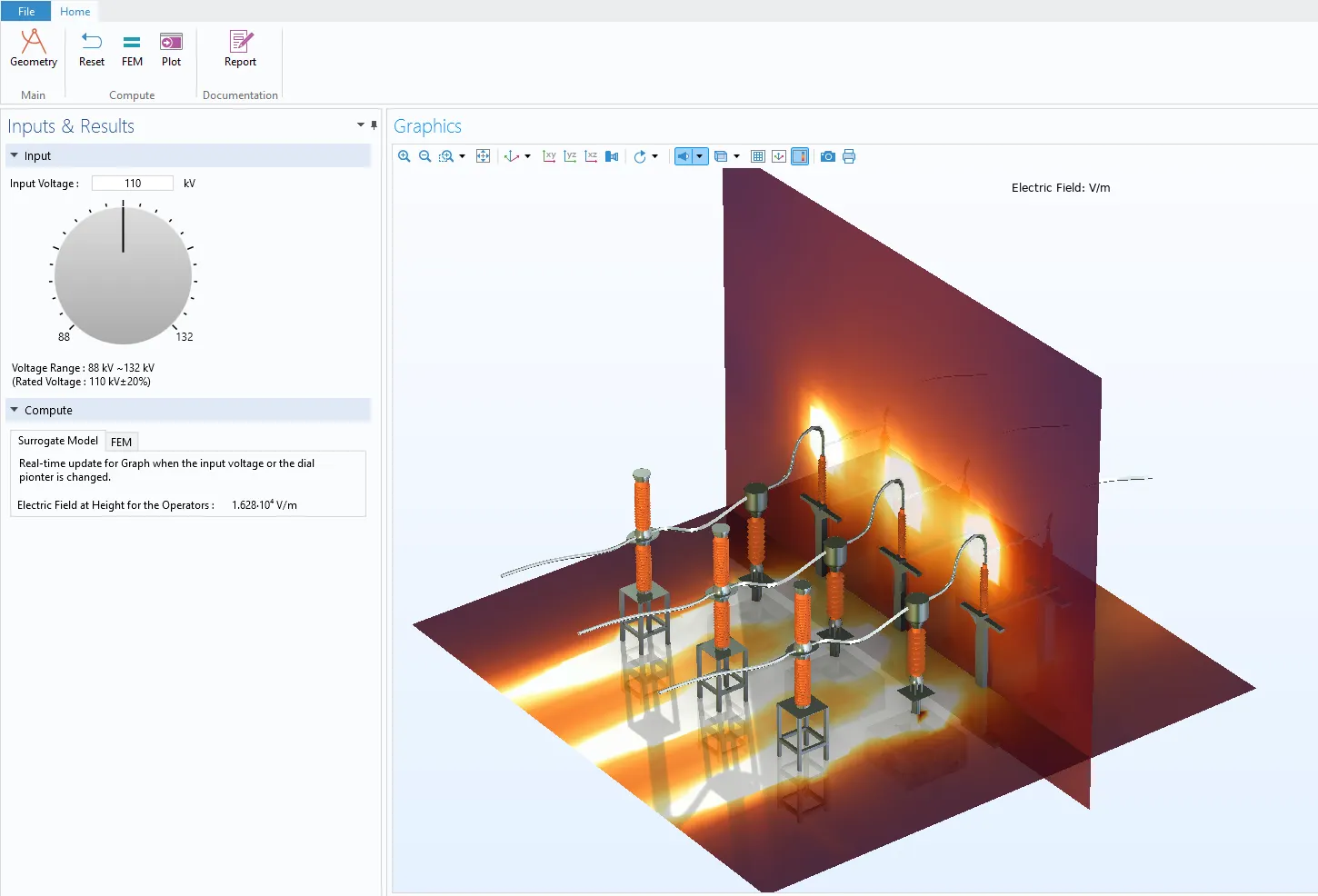

An example of a custom app built by a transformer manufacturing company for developing high-voltage switchgears. The user inputs the voltage and the results show the electric potential and electric field distribution based on an underlying computational model.

Bringing Simulation to the Field for Efficient Grid Maintenance

Even with proper design optimization by equipment manufacturers, the power grid still needs to be monitored and maintained to prevent and resolve outages and other issues. In the event of cable failure, for example, field technicians are tasked with troubleshooting and pinpointing the cause. There are a lot of factors at work: the environment where the cable is located, cable structure and material, impurities in the cable, voltage fluctuations and operating conditions. The structure is particularly complex, comprising multiple layers and a wire core of mutually insulated stranded wires.

Getting a detailed understanding of cable failure involves being able to analyze the inside of the cables, which you can do using simulation software. However, it is not practical or realistic to send a simulation engineer out with the technicians, nor is it realistic to teach the technicians how to use simulation software. But it is possible to have a simulation engineer build a custom app for troubleshooting personnel to use out in the field. A simulation app would allow them to assess cable failure based on both physics and their local onsite conditions to ultimately resolve the issue in real time. This is not a fictional example, by the way: A power grid company rolled out an app for exactly this use several years ago. By putting the power of simulation into the hands of those who need it — when they need it — utility companies can streamline R&D and keep power systems running smoothly.