“Personally, I think that a brownfield is very creative way to deal with what I think is the biggest problem that we’ve got right now, which is time and speed to market,” he said. “On a brownfield, I can go into a building that’s already got power coming into the building. Sometimes they’ve already got chiller plants, like what we’ve got with the building I’m in right now.”

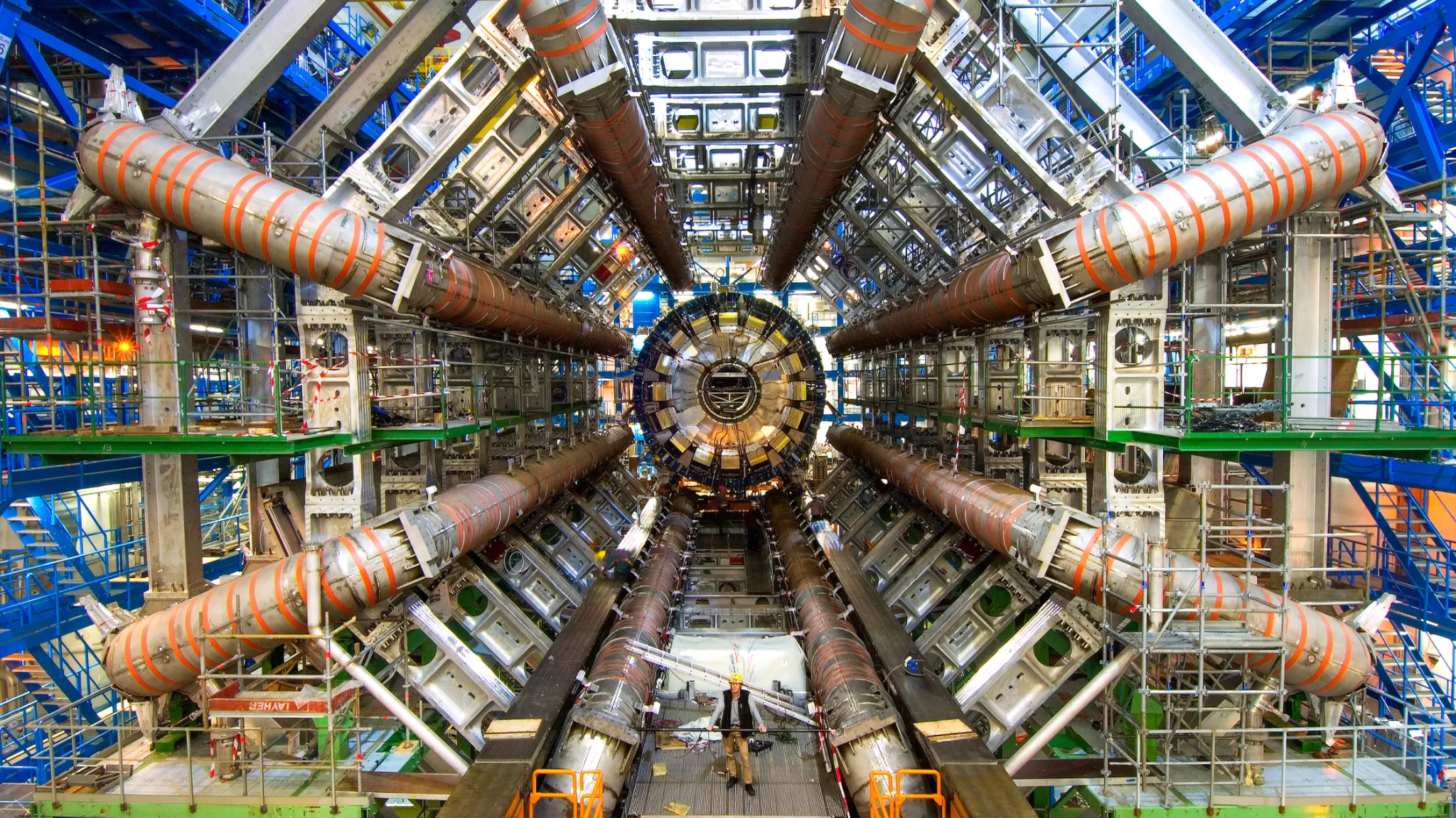

Patmos certainly made the most of the liquid facilities in the old printing press building. The facility is built to handle anywhere from 50 to over 140 kilowatts per cabinet, a leap far beyond the 1–2 kW densities typical of legacy data centers.

The chips used in the servers are Nvidia’s Grace Blackwell processors, which run extraordinarily hot. To manage this heat load, Patmos employs a multi-loop liquid cooling system. The design separates water sources into distinct, closed loops, each serving a specific function and ensuring that municipal water never directly contacts sensitive IT equipment.

“We have five different, completely separated water loops in this building,” said Morgan. “The cooling tower uses city water for evaporation, but that water never mixes with the closed loops serving the data hall. Everything is designed to maximize efficiency and protect the hardware.”

The building taps into Kansas City’s district chilled water supply, which is sourced from a nearby utility plant. This provides the primary cooling resource for the facility. Inside the data center, a dedicated loop circulates a specialized glycol-based fluid, filtered to extremely low micron levels and formulated to be electronically safe.

Heat exchangers transfer heat from the data hall fluid to the district chilled water, keeping the two fluids separate and preventing corrosion or contamination. Liquid-to-chip and rear-door heat exchangers are used for immediate heat removal.