Jim Welsh is CEO of Peak Nano.

National security requires self-reliance and independence. Today, America’s energy infrastructure and supply chain face a critical test of both.

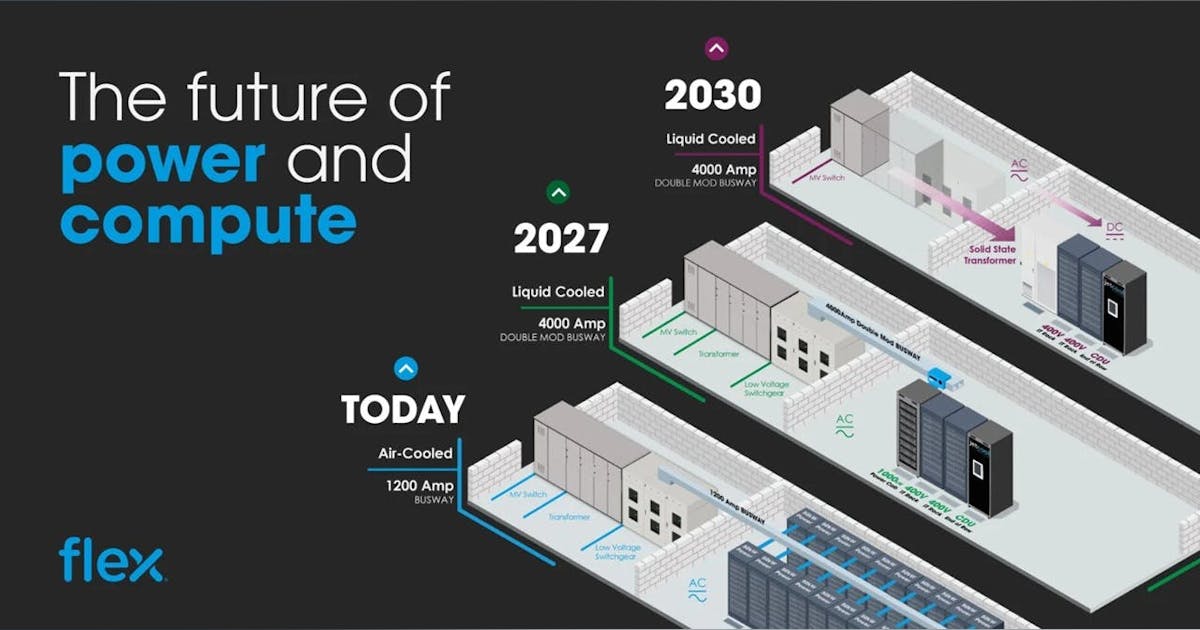

Electrification, AI, data centers and extreme weather are driving unprecedented demand for energy and grid reliability. The U.S. Department of Energy’s latest Grid Reliability Report makes one thing clear: the time for “business-as-usual” is over. The U.S. can’t keep up, let alone grow, on old infrastructure. We need a radical shift to expand, modernize and intelligently manage the grid.

Success depends on bold investments in digital technologies, enhanced equipment and advanced grid management. Together, these will enable real-time monitoring, rapid integration of renewables and far less energy lost in transmission, which today can range from 8-12% of power generation. That’s how America will meet surging demand and protect its global leadership in the AI era.

The U.S. has an Achilles’ heel: critical materials. At the heart of grid reliability are magnets, rare-earth minerals and dielectric film. These materials are often overlooked but are vital for our power infrastructure, grid reliability and every part of our energy security. Dielectric films, for example, are used in capacitors that condition power, convert AC/DC power, keep power flowing steadily and even help manage spikes in demand to keep the grid stable and secure.

The problem? The U.S. has outsourced our ability to replace failing transformers, capacitors and other critical grid components. Capacitor film — a highly engineered, ultra-thin plastic that enables power stability and distribution for our grid — is almost entirely made overseas, and 75% is made in China, which dominates the global supply.

Every year, we spend nearly $200 billion overseas for this film and other critical materials. Historically, we’ve migrated our capacity to manufacture it overseas. No American manufacturer even builds the equipment to make dielectric films.

This isn’t just an economic drain that creates risk for the U.S. It’s a huge strategic liability threatening our national security and stifling innovation at the moment our nation needs it most to drive AI and defense. To close this gap and lead the new energy era, we must reshore manufacturing and upgrade the supply chain for these core materials.

As DOE Secretary Chris Wright stated, “If we are going to keep the lights on, win the AI race, and keep electricity prices from skyrocketing, the United States must unleash American energy.”

The hidden costs of offshoring

Between subsidies and coordinated industrial strategy, China dominates clean energy supply chains. Its factories are running far beyond demand, creating an overcapacity that keeps prices low and puts Western manufacturers on the back foot.

Our reliance on foreign supply chains to uphold our energy infrastructure leaves us dangerously exposed. Our capacitor film supply could be cut off at any moment. The consequences would be immediate and severe, triggering blackouts, crippling industries and derailing America’s position in the global energy race.

Even with more limited supply disruptions, utilities could face delays, spikes in cost and worse — compromised reliability during peak events like heat domes, extreme weather and surging data center loads.

The case for reshoring

Building secure domestic supply chains for grid materials like capacitor film will fuel U.S. economic growth and technological leadership, supporting the creation of a high-skilled workforce and robust manufacturing capacity here at home. Grid-enhancing technologies also foster trust in our energy infrastructure and provide long-term cost stability for ratepayers.

We’re talking about a global film capacitor market that stood at $4.1 billion in 2024 and is projected to reach $10.3 billion by 2030, with a CAGR of 31.5%, according to Grandview Research. Beyond this market, reshoring is our path to claim billions (even trillions) in nuclear and commercial fusion, with film technology that can support high-temperature operations.

The companies and countries that control critical grid materials will set the pace for the next energy revolution.

Recent federal action — the One Big Beautiful Bill Act has changed the playing field for power strategy with its focus on expanding U.S. manufacturing, 24/7 power generation resources and U.S. sources of critical materials. However, this alone is not enough to close the gap with countries that have benefited from decades of government subsides and investment. The new Energy Dominance Financing authority, which provides loans for grid enhancement, is capped at just $1 billion, a limit other global suppliers do not have. It would cost over $25 billion just to build out the required capacitor film lines, as an example. This does not include transformers, switches, power plants, grid towers and other required equipment.

A new model for innovation

Utilities, industries and the DOE will play an integral leadership role in reshoring America’s grid. No single sector can do this alone, and forward-thinking utilities are already breaking the mold. Dominion Energy is investing in fusion, Tennessee Valley Authority and Type One Energy have partnered to develop a commercial fusion power plant, Georgia Power has added two units to the Vogtle nuclear plant and Meta is partnering with Constellation Energy to drive more energy production through nuclear power.

Instead of waiting for vendors to pitch generic solutions, these utilities are openly sharing their challenges, publishing their R&D roadmaps, and hosting innovation summits for startups and established firms to propose targeted, high-impact solutions. This lowers barriers for new entrants and aligns grid technology innovation with actual utility needs.

The message to American innovators is clear: expand domestic production, prove your worth, and utilities will test, deploy and scale your technologies.

We need more partnerships like these: targeted, transparent and focused on results. Government, industry and utilities should align around shared R&D priorities and rapid deployment, advancing focused policies and incentives. We must level the playing field for American innovators, expand our production capacity, and launch national upskilling initiatives to train the next generation of materials scientists and engineers.

What’s at stake: the US economy and security

Advanced energy materials should be treated as a central pillar in America’s economy and national security, on par with semiconductors and rare earths. Reshoring capacitor film manufacturing alone can reclaim $200 billion annually while securing today’s grid and tomorrow’s fusion revolution.

If we continue outsourcing energy supply chains, we risk national security and forfeit the economic benefits of our energy transition. America will be left scrambling for scraps while our competitors dictate the terms.

It’s not too late. By rebuilding our own foundation now, we can transform vulnerability into strength and make the U.S. the architect of the next energy era.