In partnership withDataiku

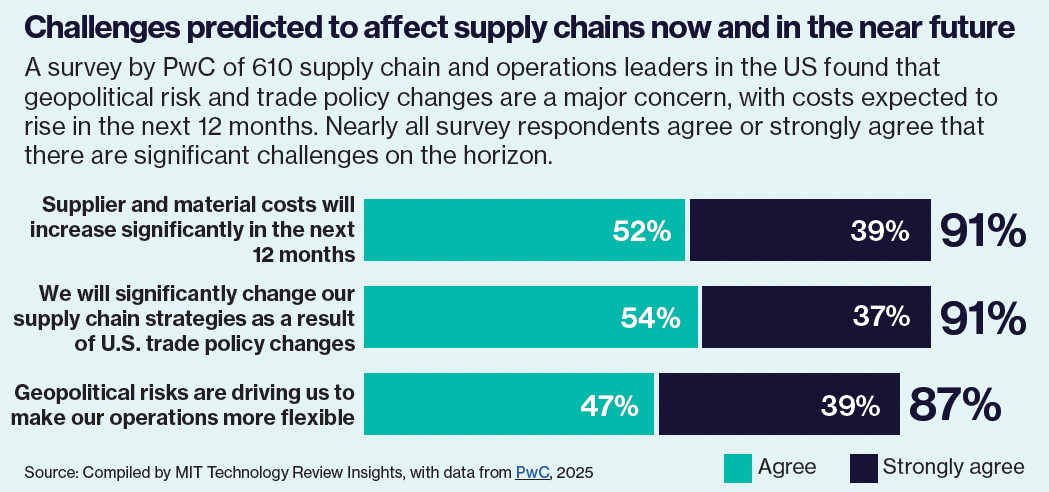

The outbreak of covid-19 laid bare the vulnerabilities of global, interconnected supply chains. National lockdowns triggered months-long manufacturing shutdowns. Mass disruption across international trade routes sparked widespread supply shortages. Costs spiralled. And wild fluctuations in demand rendered tried-and-tested inventory planning and forecasting tools useless.

“It was the black swan event that nobody had accounted for, and it threw traditional measures for risk and resilience out the window,” says Matthias Winkenbach, director of research at the MIT Center for Transportation and Logistics. “Covid-19 showed that there were vulnerabilities in the way the supply chain industry had been running for years. Just-in-time inventory, a globally interconnected supply chain, a lean supply chain—all of this broke down.”

It is not the only catastrophic event to strike supply chains in the last five years either. For example, in 2021 a six-day blockage of the Suez Canal—a narrow waterway through which 30% of global container traffic passes—added further upheaval, impacting an estimated $9.6 billion in goods each day that it remained impassable.

These shocks have been a sobering wake-up call. Now, 86% of CEOs cite resilience as a priority issue in their own supply chains. Amid ongoing efforts to better prepare for future disruptions, generative AI has emerged as a powerful tool, capable of surfacing risk and solutions to circumnavigate threats.

This content was produced by Insights, the custom content arm of MIT Technology Review. It was not written by MIT Technology Review’s editorial staff.

This content was researched, designed, and written entirely by human writers, editors, analysts, and illustrators. This includes the writing of surveys and collection of data for surveys. AI tools that may have been used were limited to secondary production processes that passed thorough human review.