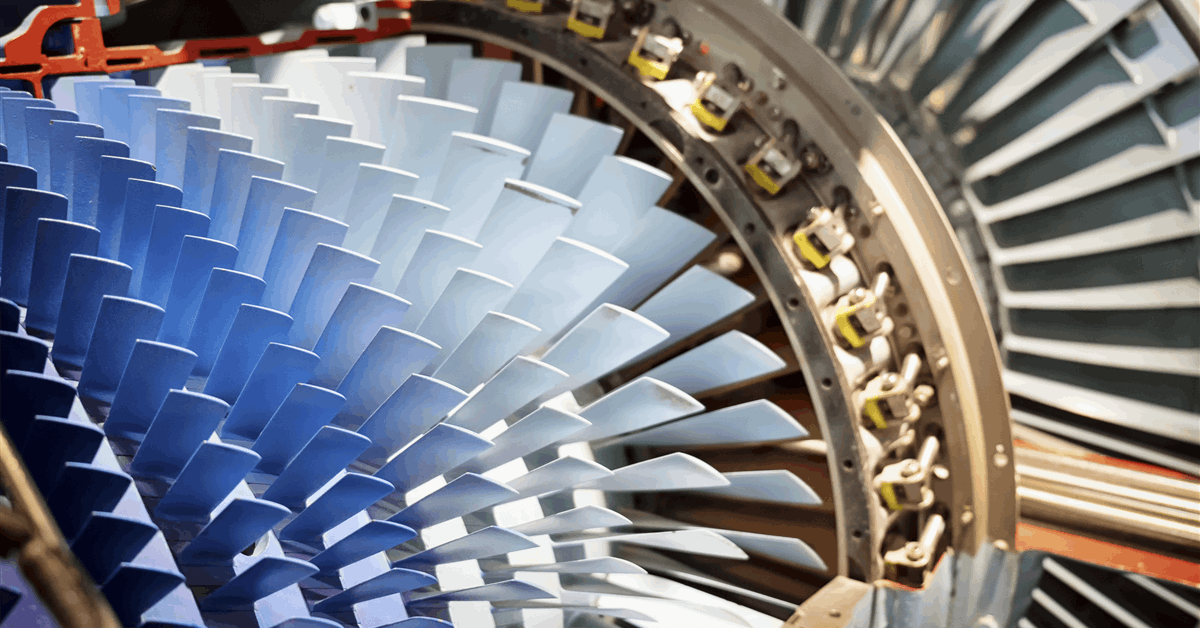

NOMAC Maintenance Energy Services (NMES), part of ACWA Power Company, has signed an agreement with Ethos Energy Group Limited (EthosEnergy) to offer an on-site Rotor Lifetime Assessment and Extension (RLE) solution for GE Frame 7E, EA, and FA gas turbines in Saudi Arabia.

This partnership represents a major advancement in delivering comprehensive on-site rotating equipment services with exceptional speed and efficiency throughout the region and beyond, EthosEnergy said in a media release.

EthosEnergy said it has expertise with mature Westinghouse gas turbines and that it is a reliable alternative OEM source for rotor, hot gas path (HGP), and compressor parts across various technologies, from GE Frame 3 to Frame 9. The company added that it has experience in designing, manufacturing, and installing Frame 7 rotors and related components.

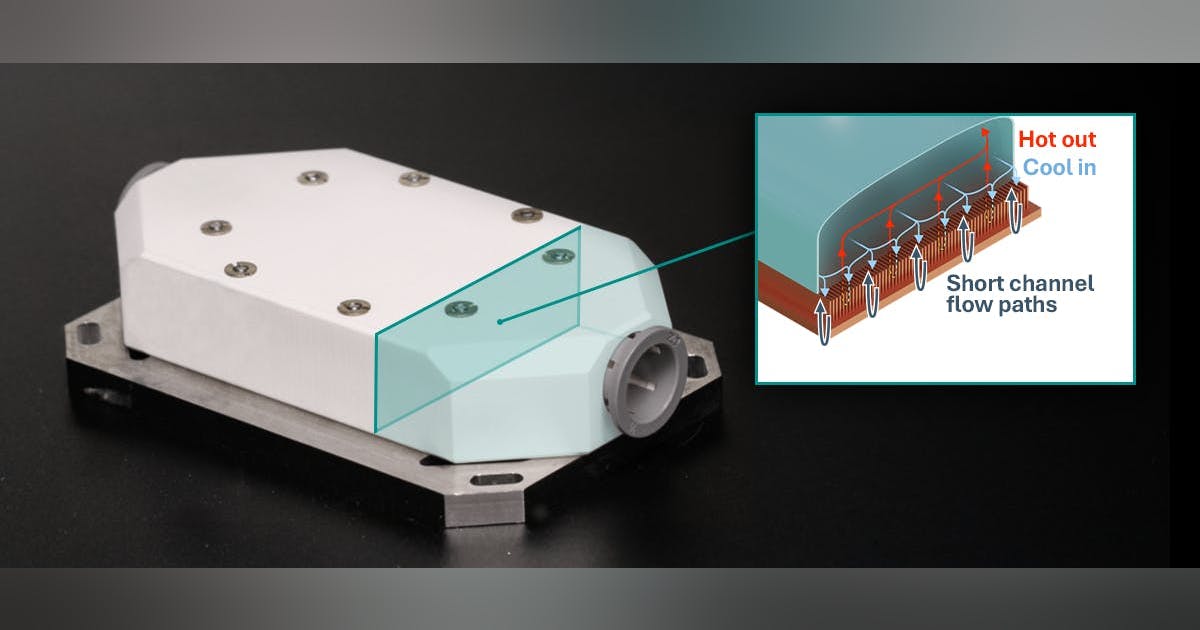

NMES, the internal long-term service division of ACWA Power, serves as a global partner for independent power producers (IPPs) and governmental utilities. NMES specializes in providing advanced workshop-level services directly at the site, offering a range of services such as rotor unstacking and restacking, laser welding and precision machining, on-site balancing and inspection, as well as essential NDT and on-site component replacement, an arrangement that mitigates the risks and delays associated with overseas transport, customs clearance, shipping, and related expenses, EthosEnergy noted.

“We’re thrilled to partner with EthosEnergy, enabling us to deliver not only the expertise and machinery to perform these works on-site, but also the required parts, providing a comprehensive solution in the shortest timeframe, and at the most competitive price”, Harald Schmit, EVP of Field Services at ACWA Power and Head of NMES, said.

Through this collaboration, EthosEnergy said it will offer a fully integrated RLE solution with NMES. The solution includes the supply of seed rotors, whether new or certified refurbished, alongside full on-site rotor lifetime assessment and extension capabilities. Additionally, the scope encompasses on-site Critical NDT (Non-Destructive Testing) and machining services, as well as parts replacement and recertification. Furthermore, technicians can perform open, close, and inspect procedures on the unit as an integral part of HGP inspection or Major Inspection.

“By combining our technical depth in rotor engineering and manufacturing with NMES’s world-class field execution, we are enabling operators to significantly reduce outage duration, cost, and risk. It’s a positive step for the region’s energy infrastructure, and we are proud to be a part of it”, Patricia Gonzalez, EthosEnergy Executive Vice President of Optimization Solutions, added.

To contact the author, email [email protected]

WHAT DO YOU THINK?

Generated by readers, the comments included herein do not reflect the views and opinions of Rigzone. All comments are subject to editorial review. Off-topic, inappropriate or insulting comments will be removed.

MORE FROM THIS AUTHOR