Uniper SE and thyssenkrupp Uhde GmbH have signed a “framework agreement” for the construction of six commercial ammonia plants toward the establishment of a scalable hydrogen import terminal in Wilhelmshaven.

The agreement builds on their demonstration project with a capacity of 28 metric tons a day of ammonia at Uniper’s Gelsenkirchen-Scholven power plant site.

The agreement licenses thyssenkrupp Uhde’s ammonia cracking technology to the German power and gas utility. It covers up to six plants with a combined capacity of 7,200 metric tons of ammonia per day.

“The agreement establishes the terms for using the technology at Uniper’s planned hydrogen import terminal in Wilhelmshaven”, a joint statement said. “The license package includes engineering, services and the supply of main equipment and catalysts.

“Uniper is currently driving forward the pre-FEED (front-end engineering and design) for a commercial plant at its Wilhelmshaven site. This pre-FEED phase will establish the design basis for the project, define its scope in more detail, further review its technoeconomic feasibility and reduce its uncertainties and risks”.

Uniper expects to launch the FEED phase by yearend 2026.

“The direct transport of hydrogen is both technically and economically challenging, while ammonia is an ideal transport and storage medium”, the statement said. “Ammonia can be liquefied relatively easily and shipped long distances in large quantities.

“Without high-performance cracker technology, large-volume imports of hydrogen are not feasible”, the statement said. “This project is therefore an important step toward establishing a resilient energy infrastructure in Europe”.

Uniper chief operating officer Holger Kreetz said, “Domestic production alone cannot meet future hydrogen demand – imports of hydrogen derivatives will be essential. Our agreement with thyssenkrupp Uhde marks a decisive next step toward enabling global hydrogen trading”.

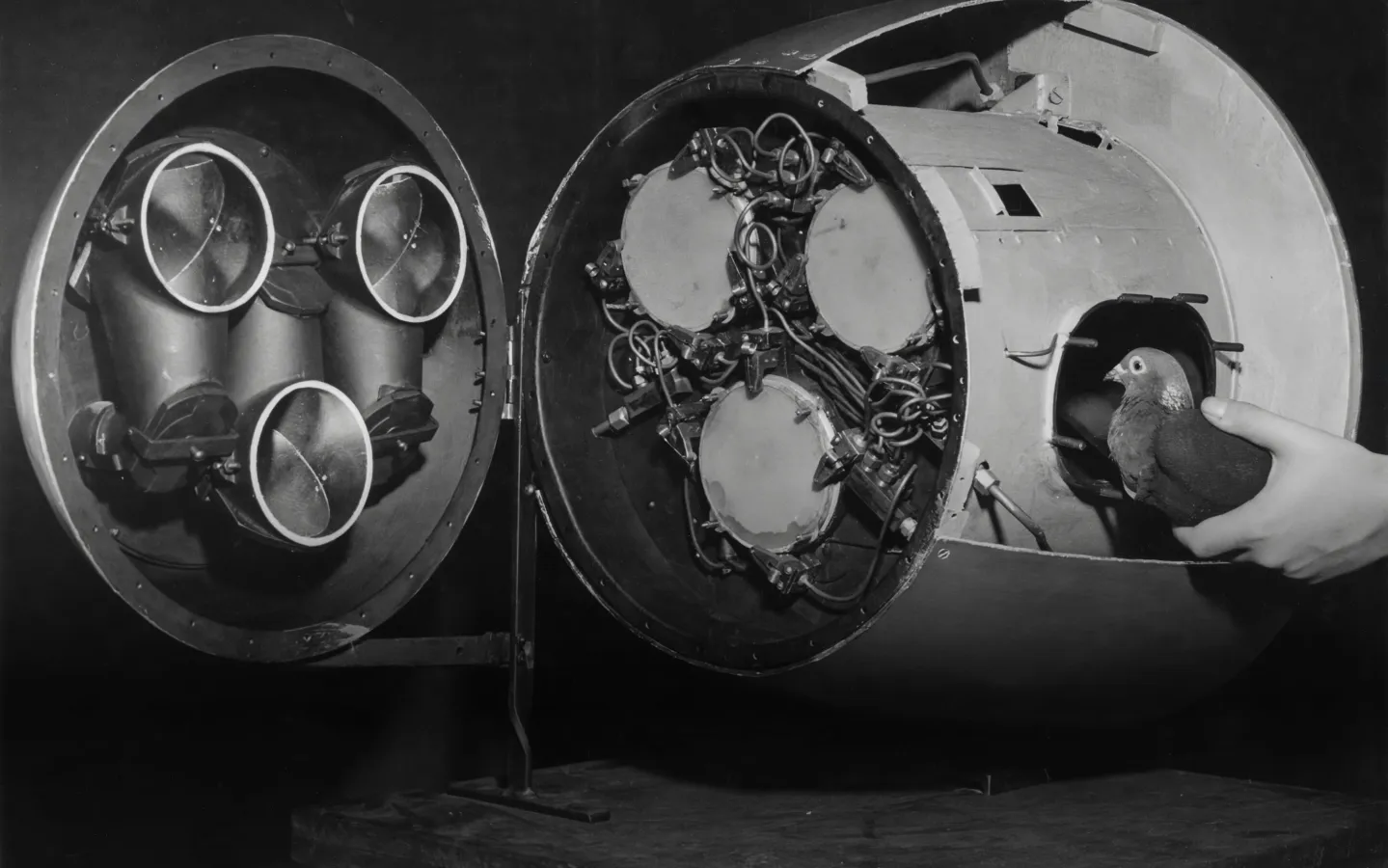

Construction has started on the demo plant, with commissioning expected next year, according to the partners. In the cracking facility, ammonia will be broken down into its components, hydrogen and nitrogen, at high temperatures. A purification process will then produce pure hydrogen, according to the companies.

“The plant will be one of the first of its kind in the world and will serve as the basis for the planned hydrogen import terminal in Wilhelmshaven, northwestern Germany, where the technology is to be applied on a large industrial scale in a second step”, said a joint statement May 27, announcing the partnership.

“The aim of the partnership is to convert imported ammonia into hydrogen on an industrial scale and make it available for a wide range of industries such as energy, steel and chemicals”.

“The project is supported by funding from the state of North Rhine-Westphalia to realize innovative components of the demonstration plant at the Scholven site … Both companies are also contributing significant funds of their own”, the companies said.

To contact the author, email [email protected]

What do you think? We’d love to hear from you, join the conversation on the

Rigzone Energy Network.

The Rigzone Energy Network is a new social experience created for you and all energy professionals to Speak Up about our industry, share knowledge, connect with peers and industry insiders and engage in a professional community that will empower your career in energy.

MORE FROM THIS AUTHOR