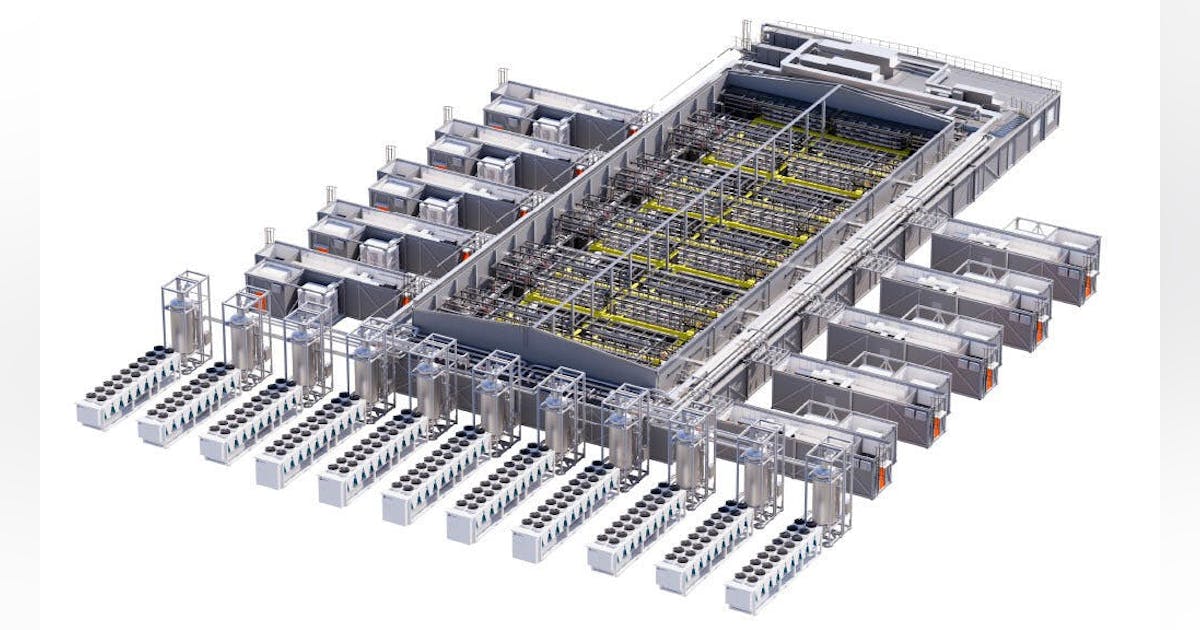

Fully Integrated Modular Design for Speed and Scale

The data center industry has increasingly embraced modular, prefabricated systems to address time, cost, and consistency pressures. OneCore stands out by delivering Vertiv’s full power and thermal stack — along with whitespace fit-out and control systems — as a single, factory-integrated solution. This eliminates the patchwork of partial modules and gives customers single-vendor responsibility. Vertiv also emphasizes deployment speed, claiming the platform can be commissioned at a rate of 1 MW per day.

In a OneCore deployment, power, cooling, and whitespace components are assembled offsite in parallel, reducing on-site complexity and schedule risk. The completed system arrives enclosed in a steel shell — a modular, turnkey building block that includes both critical infrastructure and whitespace — streamlining logistics and accelerating construction cycles.

Designed with HPC and AI factories in mind, each OneCore block can scale from 96 to 944 racks, accommodating extreme-density workloads such as GPU clusters or HPC nodes. Modules are optimized for liquid cooling and support 5 MW to 50 MW of power.

Key Vertiv technologies integrated into the platform include:

- Trinergy UPS systems, switchgear and busways for power distribution.

- CoolChip CDU, perimeter cooling, CoolLoop Trim Cooler, Liebert® AFC chiller for thermal management.

- SmartRun for overhead IT infrastructure.

- Unify centralized monitoring and control.

Meeting Efficiency and Sustainability Demands

Each block is engineered for high efficiency. Cooling is delivered through a mix of liquid (e.g., CDU and Trim Cooler) and perimeter systems, with support for advanced formats such as direct-to-chip liquid cooling — improving thermal performance and reducing energy use. Efficient UPS architectures help lower PUE and energy overhead, while power and cooling can be tailored to each module’s IT load, minimizing the risks of over- or under-provisioning.

Every module comes fully integrated with Vertiv Unify, the company’s scalable platform for unified management of power, thermal, and building systems across the entire critical infrastructure. Unify also connects to analytics-driven services — such as condition-based maintenance and incident prediction — backed by Vertiv’s global service network. This approach supports decarbonization targets through optimized power and cooling, and allows for future technology upgrades within the same modular footprint.

With modular deployments, operational expertise is critical. Vertiv’s global field service organization provides commissioning, preventive maintenance, incident response, spare-parts and crash kit availability. Field engineers receive ongoing training and certification to maintain consistent quality across global projects.

Pros and Cons of the Modular Approach

Vertiv is not the first to offer turnkey modular deployments, but is among the few delivering all major infrastructure components from a single vendor. The company positions OneCore as offering:

-

Speed to market – Rapid commissioning enabled by factory assembly and parallel onsite work.

-

Reduced on-site risk and simplified deployment – Minimal labor, streamlined coordination, and less schedule variability.

-

Scalability – Power and rack configurations scale from small enterprise to large hyperscale, with capacity added via identical modular blocks.

-

Integrated design – Whitespace, power, thermal, and controls delivered together for consistent quality.

-

Operational resilience – Built-in parallel systems and serviceability.

-

Energy efficiency – Advanced liquid cooling, high-efficiency UPS, and thermal systems aligned with sustainability goals.