Schneider Electric and Compass Datacenters: Prefabrication Meets the AI Frontier

“We’re removing bottlenecks and setting a new benchmark for AI-ready data centers.” — Aamir Paul, Schneider Electric

In another sign of how collaboration is accelerating the next wave of AI infrastructure, Schneider Electric and Compass Datacenters have joined forces to redefine the data center “white space” build-out: the heart of where power, cooling, and compute converge.

On September 9, the two companies unveiled the Prefabricated Modular EcoStruxure™ Pod, a factory-built, fully integrated white space module designed to compress construction timelines, reduce CapEx, and simplify installation while meeting the specific demands of AI-ready infrastructure.

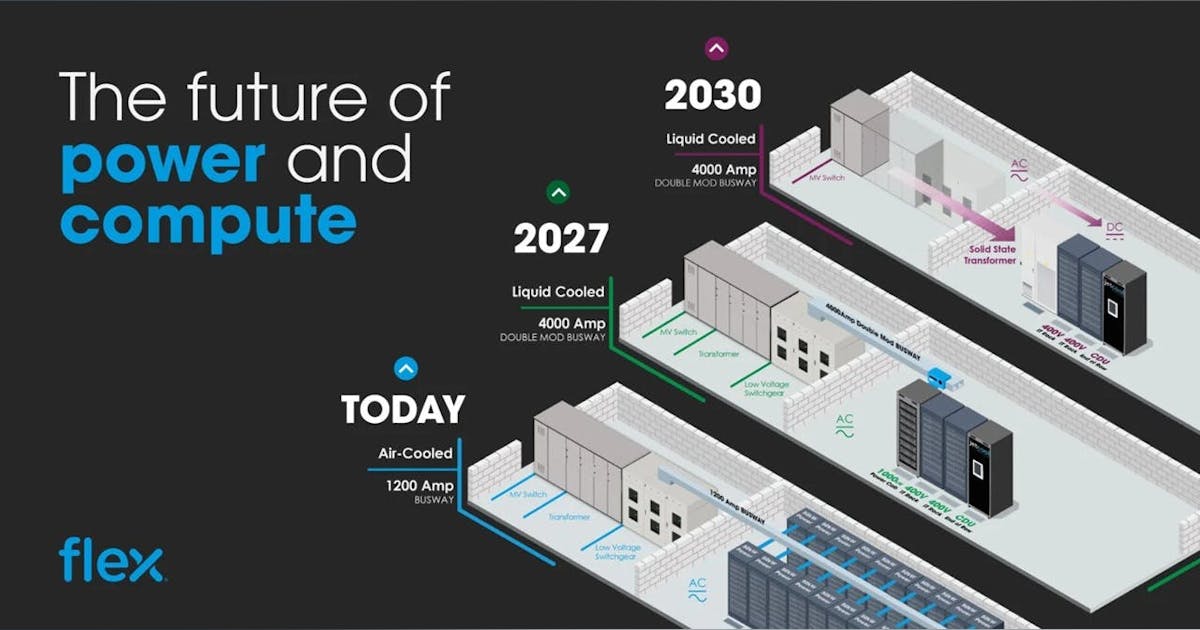

The traditional fit-out process for the IT floor (i.e. integrating power distribution, cooling systems, busways, cabling, and network components) has long been one of the slowest and most error-prone stages of data center construction. Schneider and Compass’ new approach tackles that head-on, shifting the entire workflow from fragmented on-site assembly to standardized off-site manufacturing.

“The traditional design and approach to building out power, cooling, and IT networking equipment has relied on multiple parties installing varied pieces of equipment,” the companies noted. “That process has been slow, inefficient, and prone to errors. Today’s growing demand for AI-ready infrastructure makes traditional build-outs ripe for improvement.”

Inside the EcoStruxure Pod: White Space as a Product

The EcoStruxure Pod packages every core element of a high-performance white space environment (power, cooling, and IT integration) into a single prefabricated, factory-tested unit. Built for flexibility, it supports hot aisle containment, InRow cooling, and Rear Door Heat Exchanger (RDHx) configurations, alongside high-power busways, complex network cabling, and a technical water loop for hybrid or full liquid-cooled deployments.

By manufacturing these pods off-site, Schneider Electric can deliver a complete, ready-to-install white space module that arrives move-in ready. Once delivered to a Compass Datacenters campus, the pod can be connected and commissioned with minimal field labor, dramatically reducing risk and variability.

“Over the past 14 years, we have made huge strides in designing and building data center facilities in ways that are faster, better and more sustainable,” said Chris Crosby, CEO of Compass Datacenters. “Principles like a standard kit of parts, off-site prefabrication and a tightly integrated supply chain have been gamechangers for facility construction. Now, we are applying those same principles to transform the white space fit-out process so that customers can plug in faster and more reliably than ever before.”

The EcoStruxure Pod extends the same modular philosophy Schneider and Compass pioneered for exterior shells and power blocks into the IT environment itself — effectively turning the traditionally bespoke white space into a scalable, repeatable product line.

Technical Design Advantages and Efficiency Gains

The modular pod design yields a number of significant technical and operational advantages:

- Factory Integration: Each EcoStruxure Pod is fully assembled, wired, and pressure-tested in a controlled environment before shipment, ensuring consistent quality and eliminating on-site integration errors.

- Infrastructure Simplification: The design removes the need for raised floors or ceiling grids, as the pod’s internal superstructure supports all network, power, and cooling infrastructure.

- Concurrent Construction: The pod system allows operators to build white space modules in parallel with the main facility shell, enabling “plug-in-place” installation once both are complete — a major accelerator for projects racing to bring AI capacity online.

- Reduced Manpower and Schedule Risk: Factory-built integration means less on-site labor, fewer trade interfaces, and a shorter punch list, minimizing post-installation remediation and delays.

- CapEx and Fit-Out Savings: Initial assessments by Schneider Electric and Compass indicate notable capital expenditure savings compared to traditional site-built fit-outs, driven by reduced manpower, improved installation accuracy, and elimination of redundant components.

Each pod is designed to integrate directly into existing infrastructure through modular busways, pre-engineered cable routing, and standardized manifold connections for liquid cooling loops. That flexibility allows the EcoStruxure Pod to function as a drop-in module for both new builds and phased expansions, supporting incremental scaling without disrupting live environments.

Built for AI-Ready Flexibility

At the design level, the EcoStruxure Pod reflects the broader shift toward AI-optimized data center architecture, where thermal, electrical, and mechanical systems must be co-engineered from the start. By combining Rear Door Heat Exchanger (RDHx) support with InRow cooling and technical water loops, the module is capable of serving a full spectrum of workloads, from legacy CPU racks to ultra-dense GPU pods exceeding 80–100 kW per rack.

“With EcoStruxure Pod, we’re removing bottlenecks and setting a new benchmark for AI-ready data centers — delivering the speed, resilience, and sustainability our customers need to unlock value and lead in a rapidly evolving digital landscape,” said Aamir Paul, President of North America Operations for Schneider Electric.

The collaboration builds on the same engineering principles that Schneider and Compass have used to shorten data center delivery timelines across their portfolios — namely, standardized components, off-site prefabrication, and tight supply chain integration.

Together, these principles enable what Schneider calls “end-to-end space optimization,” a strategy that treats the data hall as an engineered system, not an interior finish.

From Assembly Line to Deployment

Manufacturing of the Prefabricated Modular EcoStruxure Pods has already begun, with the first units scheduled for deployment at a Compass Datacenters campus later this fall. Each pod is factory-certified for safety and performance, then transported as a complete module to site, where Compass integrates the unit into its broader facility power and cooling ecosystem.

The result is a system that merges construction efficiency, design repeatability, and sustainability, attributes now critical to both hyperscale and enterprise AI rollouts. In Compass and Schneider’s model, white space is no longer something just to be built. It’s also something to be delivered.

AVAIO Digital and Schneider Electric: Building AI-Optimized Campuses

A week earlier, on September 3, Schneider Electric announced another major partnership, this time with AVAIO Digital Partners, to deploy next-generation power and cooling systems at four new AI-ready campuses across the U.S.

The collaboration includes advance purchases of switchgear, PDUs, UPSs, and chillers, underscoring Schneider’s growing role as both technology provider and strategic enabler.

“AVAIO has invested significantly in developing our new data center campuses across the U.S. and is now ready to commence construction,” said Mark McComiskey, CEO of AVAIO Digital. “Our partnership with Schneider Electric is a key component of our strategy to develop facilities that provide the next-generation power and cooling needed for successful AI and Cloud infrastructure deployments.”

Schneider’s Vandana Singh, Senior Vice President of Data Center Business, noted that the collaboration “enables customers to deploy their critical IT infrastructure rapidly at the heart of a new generation of data center campuses that uniquely address the needs of AI.”

The partnership integrates Schneider’s EcoDesign principles to reduce embedded carbon, along with condition-based maintenance models and data-driven predictive analytics to extend asset life and reduce downtime, and signifies an industry shift from static equipment deployment to continuously optimized infrastructure.