You live in a house you designed and built yourself. You rely on the sun for power, heat your home with a woodstove, and farm your own fish and vegetables. The year is 2025.

This is the life of Marcin Jakubowski, the 53-year-old founder of Open Source Ecology, an open collaborative of engineers, producers, and builders developing what they call the Global Village Construction Set (GVCS). It’s a set of 50 machines—everything from a tractor to an oven to a circuit maker—that are capable of building civilization from scratch and can be reconfigured however you see fit.

Jakubowski immigrated to the US from Slupca, Poland, as a child. His first encounter with what he describes as the “prosperity of technology” was the vastness of the American grocery store. Seeing the sheer quantity and variety of perfectly ripe produce cemented his belief that abundant, sustainable living was within reach in the United States.

With a bachelor’s degree from Princeton and a doctorate in physics from the University of Wisconsin, Jakubowski had spent most of his life in school. While his peers kick-started their shiny new corporate careers, he followed a different path after he finished his degree in 2003: He bought a tractor to start a farm in Maysville, Missouri, eager to prove his ideas about abundance. “It was a clear decision to give up the office cubicle or high-level research job, which is so focused on tiny issues that one never gets to work on the big picture,” he says. But in just a short few months, his tractor broke down—and he soon went broke.

Every time his tractor malfunctioned, he had no choice but to pay John Deere for repairs—even if he knew how to fix the problem on his own. John Deere, the world’s largest manufacturer of agricultural equipment, continues to prohibit farmers from repairing their own tractors (except in Colorado, where farmers were granted a right to repair by state law in 2023). Fixing your own tractor voids any insurance or warranty, much like jailbreaking your iPhone.

Today, large agricultural manufacturers have centralized control over the market, and most commercial tractors are built with proprietary parts. Every year, farmers pay $1.2 billion in repair costs and lose an estimated $3 billion whenever their tractors break down, entirely because large agricultural manufacturers have lobbied against the right to repair since the ’90s. Currently there are class action lawsuits involving hundreds of farmers fighting for their right to do so.

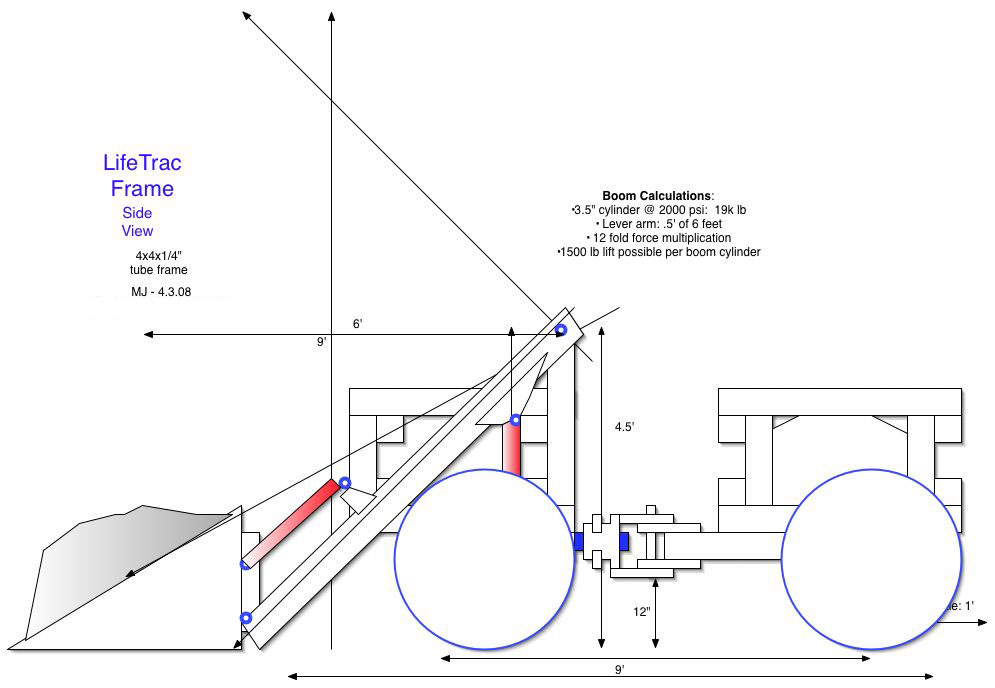

“The machines own farmers. The farmers don’t own [the machines],” Jakubowski says. He grew certain that self-sufficiency relied on agricultural autonomy, which could be achieved only through free access to technology. So he set out to apply the principles of open-source software to hardware. He figured that if farmers could have access to the instructions and materials required to build their own tractors, not only would they be able to repair them, but they’d also be able to customize the vehicles for their needs. Life-changing technology should be available to all, he thought, not controlled by a select few. So, with an understanding of mechanical engineering, Jakubowski built his own tractor and put all his schematics online on his platform Open Source Ecology.

That tractor Jakubowski built is designed to be taken apart. It’s a critical part of the GVCS, a collection of plug-and-play machines that can “build a thriving economy anywhere in the world … from scratch.” The GVCS includes a 3D printer, a self-contained hydraulic power unit called the Power Cube, and more, each designed to be reconfigured for multiple purposes. There’s even a GVCS micro-home. You can use the Power Cube to power a brick press, a sawmill, a car, a CNC mill, or a bioplastic extruder, and you can build wind turbines with the frames that are used in the home.

Jakubowski compares the GVCS to Lego blocks and cites the Linux ecosystem as his inspiration. In the same way that Linux’s source code is free to inspect, modify, and redistribute, all the instructions you need to build and repurpose a GVCS machine are freely accessible online. Jakubowski envisions a future in which the GVCS parallels the Linux infrastructure, with custom tools built to optimize agriculture, construction, and material fabrication in localized contexts. “The [final form of the GVCS] must be proven to allow efficient production of food, shelter, consumer goods, cars, fuel, and other goods—except for exotic imports (coffee, bananas, advanced semiconductors),” he wrote on his Open Source Ecology wiki.

The ethos of GVCS is reminiscent of the Whole Earth Catalog, a countercultural publication that offered a combination of reviews, DIY manuals, and survival guides between 1968 and 1972. Founded by Stewart Brand, the publication had the slogan “Access to tools” and was famous for promoting self-sufficiency. It heavily featured the work of R. Buckminster Fuller, an American architect known for his geodesic domes (lightweight structures that can be built using recycled materials) and for coining the term “ephemeralization,” which refers to the ability of technology to let us do more with less material, energy, and effort.

Jakubowski owns the publication’s entire printed output, but he offers a sharp critique of its legacy in our current culture of tech utopianism. “The first structures we built were domes. Good ideas. But the open-source part of that was not really there yet—Fuller patented his stuff,” he says. Fuller and the Whole Earth Catalog may have popularized an important philosophy of self-reliance, but to Jakubowski, their failure to advocate for open collaboration stopped the ultimate vision of sustainability from coming to fruition. “The failure of the techno-utopians to organize into a larger movement of collaborative, open, distributed production resulted in a miscarriage of techno-utopia,” he says.

Unlike software, hardware can’t be infinitely reproduced or instantly tested. It requires manufacturing infrastructure and specific materials, not to mention exhaustive documentation. There are physical constraints—different port standards, fluctuations in availability of materials, and more. And now that production chains are so globalized that manufacturing a hot tub can require parts from seven different countries and 14 states, how can we expect anything to be replicable in our backyard? The solution, according to Jakubowski, is to make technology “appropriate.”

Appropriate technology is technology that’s designed to be affordable and sustainable for a specific local context. The idea comes from Gandhi’s philosophy of swadeshi (self-reliance) and sarvodaya (upliftment of all) and was popularized by the economist Ernst Friedrich “Fritz” Schumacher’s book Small Is Beautiful, which discussed the concept of “intermediate technology”: “Any intelligent fool can make things bigger, more complex, and more violent. It takes a touch of genius—and a lot of courage—to move in the opposite direction.” Because different environments operate at different scales and with different resources, it only makes sense to tailor technology for those conditions. Solar lamps, bikes, hand-powered water pumps—anything that can be built using local materials and maintained by the local community—are among the most widely cited examples of appropriate technology.

This concept has historically been discussed in the context of facilitating economic growth in developing nations and adapting capital-intensive technology to their needs. But Jakubowski hopes to make it universal. He believes technology needs to be appropriate even in suburban and urban places with access to supermarkets, hardware stores, Amazon deliveries, and other forms of infrastructure. If technology is designed specifically for these contexts, he says, end-to-end reproduction will be possible, making more space for collaboration and innovation.

What makes Jakubowski’s technology “appropriate” is his use of reclaimed materials and off-the-shelf parts to build his machines. By using local materials and widely available components, he’s able to bypass the complex global supply chains that proprietary technology often requires. He also structures his schematics around concepts already familiar to most people who are interested in hardware, making his building instructions easier to follow.

Everything you need to build Jakubowski’s machines should be available around you, just as everything you need to know about how to repair or operate the machine is online—from blueprints to lists of materials to assembly instructions and testing protocols. “If you’ve got a wrench, you’ve got a tractor,” his manual reads.

This spirit dates back to the ’70s, when the idea of building things “moved out of the retired person’s garage and into the young person’s relationship with the Volkswagen,” says Brand. He references John Muir’s 1969 book How to Keep Your Volkswagen Alive: A Manual of Step-by-Step Procedures for the Compleat Idiot and fondly recalls how the Beetle’s simple design and easily swapped parts made it common for owners to rebody their cars, combining the chassis of one with the body of another. He also mentions the impact of the Ford Model T cars that, with a few extra parts, were made into tractors during the Great Depression.

For Brand, the focus on repairability is critical in the modern context. There was a time when John Deere tractors were “appropriate” in Jakubowski’s terms, Brand says: “A century earlier, John Deere took great care to make sure that his plowshares could be taken apart and bolted together, that you can undo and redo them, replace parts, and so on.” The company “attracted insanely loyal customers because they looked out for the farmers so much,” Brand says, but “they’ve really reversed the orientation.” Echoing Jakubowski’s initial motivation for starting OSE, Brand insists that technology is appropriate to the extent that it is repairable.

Even if you can find all the parts you need from Lowe’s, building your own tractor is still intimidating. But for some, the staggering price advantage is reason enough to take on the challenge: A GVCS tractor costs $12,000 to build, whereas a commercial tractor averages around $120,000 to buy, not including the individual repairs that might be necessary over its lifetime at a cost of $500 to $20,000 each. And gargantuan though it may seem, the task of building a GVCS tractor or other machine is doable: Just a few years after the project launched in 2008, more than 110 machines had been built by enthusiasts from Chile, Nicaragua, Guatemala, China, India, Italy, and Turkey, just to name a few places.

Of the many machines developed, what’s drawn the most interest from GVCS enthusiasts is the one nicknamed “The Liberator,” which presses local soil into compressed earth blocks, or CEBs—a type of cost- and energy-efficient brick that can withstand extreme weather conditions. It’s been especially popular among those looking to build their own homes: A man named Aurélien Bielsa replicated the brick press in a small village in the south of France to build a house for his family in 2018, and in 2020 a group of volunteers helped a member of the Open Source Ecology community build a tiny home using blocks from one of these presses in a fishing village near northern Belize.

Jakubowski recalls receiving an email about one of the first complete reproductions of the CEB press, built by a Texan named James Slate, who ended up starting a business selling the bricks: “When [James] sent me a picture [of our brick press], I thought it was a Photoshopped copy of our machine, but it was his. He just downloaded the plans off the internet. I knew nothing about it.” Slate described having a very limited background in engineering before building the brick press. “I had taken some mechanics classes back in high school. I mostly come from an IT computer world,” he said in an interview with Open Source Ecology. “Pretty much anyone can build one, if they put in the effort.”

Andrew Spina, an early GVCS enthusiast, agrees. Spina spent five years building versions of the GVCS tractor and Power Cube, eager to create means of self-sufficiency at an individual scale. “I’m building my own tractor because I want to understand it and be able to maintain it,” he wrote in his blog, Machining Independence. Spina’s curiosity gestures toward the broader issue of technological literacy: The more we outsource to proprietary tech, the less we understand how things work—further entrenching our need for that proprietary tech. Transparency is critical to the open-source philosophy precisely because it helps us become self-sufficient.

Since starting Open Source Ecology, Jakubowski has been the main architect behind the dozens of machines available on his platform, testing and refining his designs on a plot of land he calls the Factor e Farm in Maysville. Most GVCS enthusiasts reproduce Jakubowski’s machines for personal use; only a few have contributed to the set themselves. Of those select few, many made dedicated visits to the farm for weeks at a time to learn how to build Jakubowski’s GVCS collection. James Wise, one of the earliest and longest-term GVCS contributors, recalls setting up tents and camping out in his car to attend sessions at Jakubowski’s workshop, where visiting enthusiasts would gather to iterate on designs: “We’d have a screen on the wall of our current best idea. Then we’d talk about it.” Wise doesn’t consider himself particularly experienced on the engineering front, but after working with other visiting participants, he felt more emboldened to contribute. “Most of [my] knowledge came from [my] peers,” he says.

Jakubowski’s goal of bolstering collaboration hinges on a degree of collective proficiency. Without a community skilled with hardware, the organic innovation that the open-source approach promises will struggle to bear fruit, even if Jakubowski’s designs are perfectly appropriate and thoroughly documented.

“That’s why we’re starting a school!” said Jakubowski, when asked about his plan to build hardware literacy. Earlier this year, he announced the Future Builders Academy, an apprenticeship program where participants will be taught all the necessary skills to develop and build the affordable, self-sustaining homes that are his newest venture. Seed Eco Homes, as Jakubowski calls them, are “human-sized, panelized” modular houses complete with a biodigester, a thermal battery, a geothermal cooling system, and solar electricity. Each house is entirely energy independent and can be built in five days, at a cost of around $40,000. Over eight of these houses have been built across the country, and Jakubowski himself lives in the earliest version of the design. Seed Eco Homes are the culmination of his work on the GVCS: The structure of each house combines parts from the collection and embodies its modular philosophy. The venture represents Jakubowski’s larger goal of making everyday technology accessible. “Housing [is the] single largest cost in one’s life—and a key to so much more,” he says.

The final goal of Open Source Ecology is a “zero marginal cost” society, where producing an additional unit of a good or service costs little to nothing. Jakubowski’s interpretation of the concept (popularized by the American economist and social theorist Jeremy Rifkin) assumes that by eradicating licensing fees, decentralizing manufacturing, and fostering collaboration through education, we can develop truly equitable technology that allows us to be self-sufficient. Open-source hardware isn’t just about helping farmers build their own tractors; in Jakubowski’s view, it’s a complete reorientation of our relationship to technology.

In the first issue of the Whole Earth Catalog, a key piece of inspiration for Jakubowski’s project, Brand wrote: “We are as gods and we might as well get good at it.” In 2007, in a book Brand wrote about the publication, he corrected himself: “We are as gods and have to get good at it.” Today, Jakubowski elaborates: “We’re becoming gods with technology. Yet technology has badly failed us. We’ve seen great progress with civilization. But how free are people today compared to other times?” Cautioning against our reliance on the proprietary technology we use daily, he offers a new approach: Progress should mean not just achieving technological breakthroughs but also making everyday technology equitable.

“We don’t need more technology,” he says. “We just need to collaborate with what we have now.”

Tiffany Ng is a freelance writer exploring the relationship between art, tech, and culture. She writes Cyber Celibate, a neo-Luddite newsletter on Substack.