The NATO Innovation Fund (NIF) said it had led a financing round with participation from Norwegian sovereign investment fund Investinor AS for Kongsberg Ferrotech AS, a Norwegian company offering robotic solutions for the maintenance and repair of offshore infrastructure including oil and gas facilities.

The support will help Kongsberg Ferrotech, whose offerings have already been deployed by energy giants, grow its reach across North Atlantic Treaty Organization countries, according to a statement posted on NIF’s website.

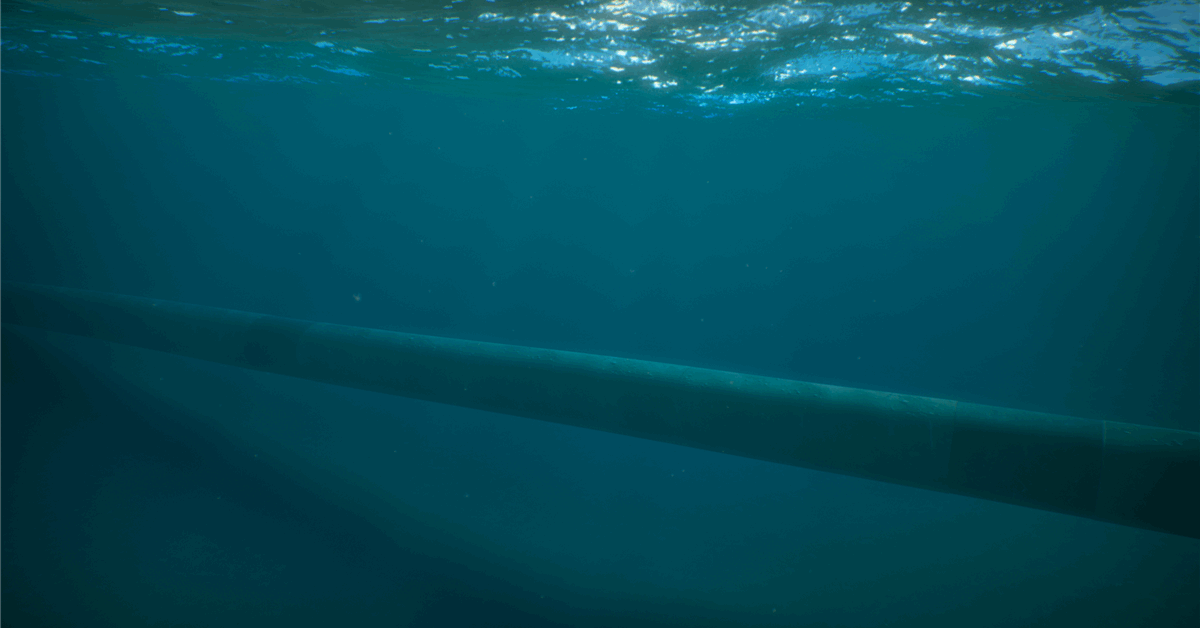

For pipelines, Kongsberg Ferrotech has developed a set of robotic solutions called Nautilus to reduce inspection and repair time to just days.

“With about 160,000-kilometer subsea pipelines around the world, unmitigated leaks are causing environmental spills on a daily basis. A typical inspection and repair campaign using conventional technology can take from weeks to months – involving very expensive vessels, manual divers and a number of suppliers. The repair cost alone runs into millions of dollars. If production shut-down is required, the total cost can easily reach tens of millions”, the statement said.

With diver-free Nautilus, “most repairs can be performed without affecting the production, offering significant cost savings and up to 70 percent reduction in response time and C02 footprint”, the statement said.

It added, “Kongsberg Ferrotech enables in-situ repair of critical submerged assets – extending their life – by creating a water-evacuated ‘dry habitat’ at depth. Its patented technology can seal and evacuate water around areas to be repaired”.

“The company’s unique robotic platform – where both inspection and repair are performed in the same operation and in the same dive – can address a wide range of subsea assets from pipelines and risers to wind-turbine monopiles and merchant marine vessels”, the statement said. “When a defect is identified, the robot can deliver a specifically tailored repair; either a ‘cold’, non-metallic repair or a hot, 3D printed permanent repair.

“With this technology, true subsea asset rejuvenation becomes a reality in a sustainable manner, enabling continuous maintenance in place of expensive and time-consuming replacement.

“Kongsberg Ferrotech is working with world-leading energy operators from PTTEP of Thailand to ADNOC, Aramco, Total Energies and Petrobras to adapt the Kongsberg Ferrotech Technology to optimally support their operations.

“Additionally, since 2021, Kongsberg Ferrotech has successfully completed a significant joint industry project with partners Equinor, Gassco, Shell International and SINTEF to develop advanced 3D printing technologies for in situ, metal to metal, repairs of underwater assets”.

NIF senior associate Ben Balmforth commented, “Kongsberg Ferrotech is already driving long-term resilience in strategically vital sectors. We are excited for the company to expand its reach across the Alliance, enabling secure, cost-effective, and never-before-possible repair and maintenance for critical infrastructure”.

Last January the Baltic Sea NATO Allies Summit committed to intensifying efforts in protecting energy and other critical undersea infrastructure, citing the environmental threat of what the Allies say is a “shadow fleet” of Russian oil tankers, as well as threats of sabotage.

In May NATO’s Critical Undersea Infrastructure Network gathered civilian and military authorities, industry stakeholders and experts from across the alliance to discuss “innovative approaches to detecting suspicious activities and securing vital undersea assets, including through new sensing and monitoring technologies”, according to a NATO statement.

To contact the author, email [email protected]

What do you think? We’d love to hear from you, join the conversation on the

Rigzone Energy Network.

The Rigzone Energy Network is a new social experience created for you and all energy professionals to Speak Up about our industry, share knowledge, connect with peers and industry insiders and engage in a professional community that will empower your career in energy.

MORE FROM THIS AUTHOR